EPR

Feb 9, 2026

Biki John

Senior Content Marketing Manager

Key Takeaways

Understand the key packaging EPR law in Oregon (SB 582).

Discover how eco-modulation links Life Cycle Assessments (LCAs) to packaging fee bonuses.

Learn how a digital platform can help companies navigate complex and evolving packaging EPR laws.

Oregon | Packaging Accountability

Across the United States, Extended Producer Responsibility (EPR) laws are rapidly gaining traction, fundamentally redefining how businesses manage the role of packaging. Leading this regulatory wave is Oregon's Plastic Pollution and Recycling Modernisation Act, Senate Bill 582 (SB 582).

This legislation shifts financial responsibility for waste management from local taxpayers to the product brands, demanding a new level of environmental accountability. For companies distributing goods in Oregon, it is no longer sufficient to rely on vague sustainability promises; SB 582 requires timely reporting and verifiable reductions in environmental impact.

At its core, Oregon’s SB 582 is designed to achieve three main goals:

Modernise and improve the state’s recycling infrastructure.

Transfer the costs of the recycling system from local authorities to the obligated producers.

Create financial incentives for more sustainable packaging design.

Essential Compliance for Producers

To meet the requirements of this law, producers must first affiliate with a Producer Responsibility Organisation (PRO). Following registration, they are obligated to submit granular, detailed data, broken down by material, for every covered product sold within the state. This demand for data precision and transparency is a non-negotiable step in the compliance process.

Eco-Modulation: Turning Design into Savings

A distinguishing feature of SB 582 is its comprehensive use of eco-modulation bonuses. These fee adjustments are rewards designed to encourage producers to exceed minimum compliance standards and actively improve the sustainability of their packaging portfolio. These bonuses recognise demonstrable efforts to reduce environmental harm, transforming compliance from a cost centre into a strategic source of cost reduction.

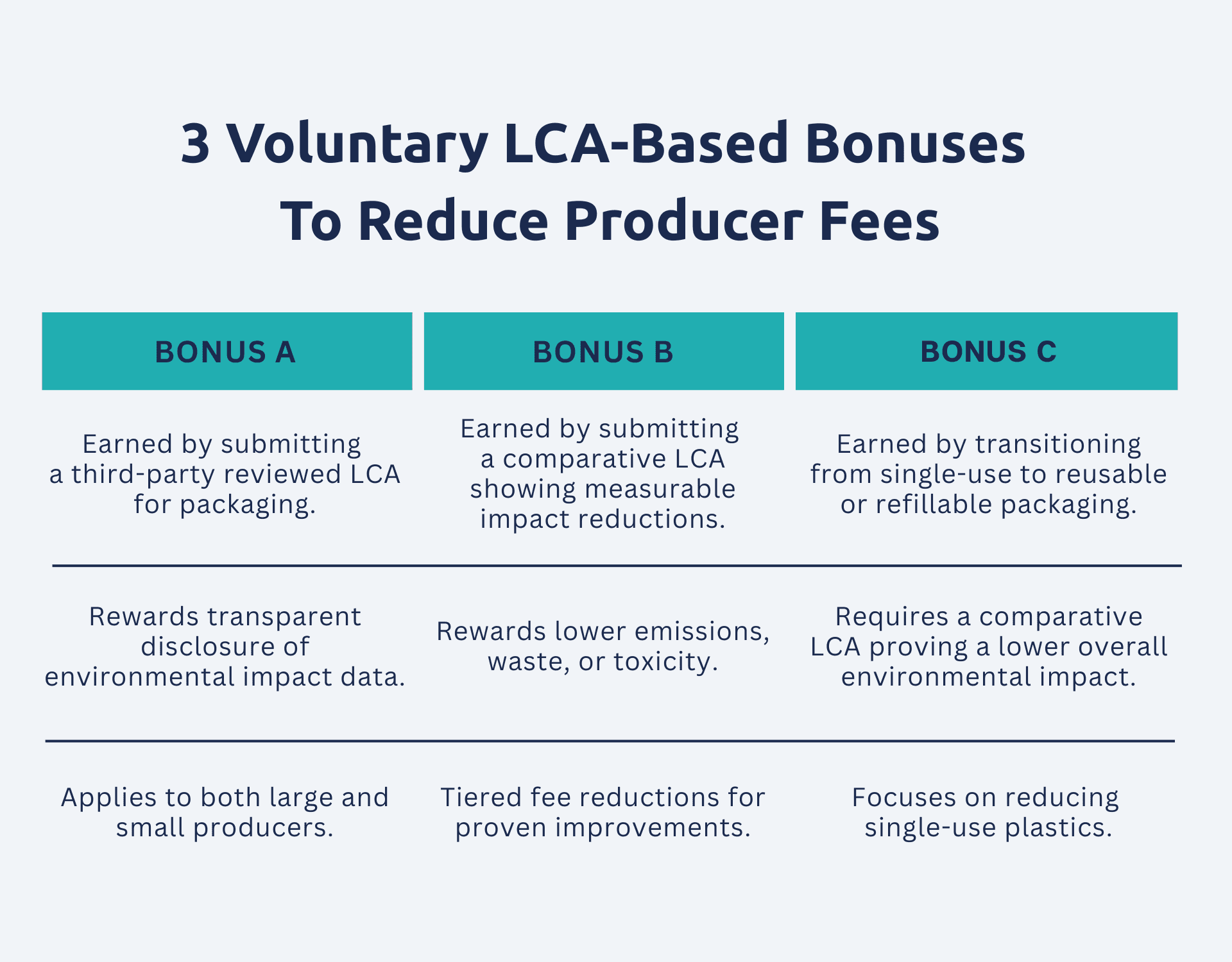

The key opportunities for producers to earn reduced fees are categorised into three voluntary bonuses, all linked to Life Cycle Assessments (LCAs):

Bonus A: Disclosure of Environmental Impact

This bonus provides a significant incentive for businesses to complete and submit a third-party reviewed LCA for their packaging systems.

While large producers (those responsible for over 1% of the state’s product volume) must submit LCAs, this bonus makes the process financially attractive even for smaller businesses.

The reward is linked to the initial disclosure of detailed environmental impact data.

Bonus B: Reductions Through Packaging Redesign

To qualify for this bonus, producers must submit a comparative LCA that quantifies specific and measurable reductions in the environmental impact of their primary packaging, such as decreases in emissions, waste, or toxicity.

This bonus is aimed at rewarding active improvement and optimisation of existing packaging designs.

Companies that demonstrate clear reductions are eligible for tiered fee reductions.

Bonus C: The Shift to Circular Formats

This incentive is designed to reward brands that move away from single-use packaging.

Qualification requires a comparative LCA proving that transitioning to reusable or refillable packaging systems results in verifiable reductions in overall environmental impact, particularly concerning single-use plastics.

The Need for Data Accuracy

Oregon’s SB 582, alongside other emerging EPR programmes, confirms that reliance on inadequate data and manual processes will lead to compliance failure. These regulations demand accurate, traceable, and detailed packaging specifications. Companies that struggle with fragmented data sources and manual reporting face potential penalties and missed opportunities for significant fee savings. The future of compliance and sustainability leadership relies entirely on using centralised, high-quality data to ensure all reporting and design claims are accurate and audit-ready.

How Can Brand Owners Navigate the Digital Path to EPR Readiness?

The looming rollout of EPR and eco-modulation mandates across North America demands a fundamental move away from siloed data and static assessments. To address this urgent industry requirement, Recyda has collaborated with the Association of Plastic Recyclers (APR) to launch the APR Design Assessment Tool.

This digital solution, arriving in early 2026, is purpose-built to revolutionise how businesses analyse and enhance the circularity of their plastic packaging ranges. By digitally embedding the definitive APR Design Guide, the platform provides teams with real-time, automated verification during the initial design and development phases.

This proactive capability allows organisations to pinpoint design friction early and rectify data gaps, ensuring all packaging aligns with the rigorous recyclability standards now being codified into law. Such an integrated approach is vital for de-risking supply chains, defending sustainability claims with auditable data, and insulating the business against the rising cost of eco-modulation penalties.

Ultimately, Recyda’s comprehensive platform provides a unified global solution. While the APR Design Assessment Tool serves the specific needs of the North American market, our centralised system also simplifies EPR declarations and reporting across Europe, ensuring your compliance strategy is seamless on both sides of the Atlantic.

From Oregon to International Strategy

While Oregon’s SB 582 represents a landmark shift for North American producers, it is only one piece of an increasingly complex international puzzle. As we move through 2026, the era of simple, flat-fee compliance is ending, replaced by a sophisticated international landscape where financial liability is tied directly to granular design choices.

For companies operating across borders, navigating the "fragmentation vs. harmonisation" divide is no longer optional; it is a financial necessity. To help you anticipate these shifts and protect your bottom line, we have launched our comprehensive EPR Trends Report 2026, providing the strategic roadmap needed to manage compliance.

Download our report to:

Discover why countries like Belgium are seeing a nearly 10% increase in plastic rates while Spain is implementing a 9.85% decrease, and what this "split" means for your 2026 budget.

Learn how new EPR frameworks (e.g. in Portugal) are moving beyond simple fees to implement tiered "bonus/malus" rewards that can fluctuate your costs by as much as 10% based on specific recyclability attributes.

Stay ahead of the North American 2026 deadlines, and understand how the Circular Action Alliance (CAA) is centralising the compliance roadmap for U.S. producers.

Understand why traditional manual tracking is no longer feasible in an era of rapidly changing rates and emerging schemes, and why a digital-first approach is now the only viable path to global compliance.

Download our report to learn about the EPR developments across the globe and what 2026 has in store for your region.