Packaging Data

Packaging Compliance

Jan 13, 2026

Shahan Syed

Product Marketing Manager

Key Takeaways

Recognize that compliance readiness requires solving four distinct challenges: scattered, unstructured, incomplete, and inaccurate packaging data.

Read more on how to strategically approach and solve these challenges.

Explore how Recyda’s platform can help turn this complexity into compliance-ready data.

The term 'data complexity' often surfaces in discussions about meeting stringent packaging compliance requirements.

But what does this complexity truly entail, and, more importantly, what actionable steps can companies take to simplify it?

Drawing upon our experience with large enterprises over the last few years, we have prepared this article to help you understand the different dimensions in which you should think when it comes to packaging data and related compliance.

Understanding the Four Dimensions of Packaging Data Challenges

While most enterprise customers encounter difficulties with their packaging data, these problems are highly varied and rarely identical across organizations, often stemming directly from unique internal company structures, diverse supply chain setups, and existing IT systems.

Despite this diversity in complexity and scope, the most universal and foundational challenge they share is ensuring data completeness, a critical baseline upon which all accurate recyclability assessments and Extended Producer Responsibility (EPR) reporting must be built.

Below, we detail the common problems observed across four critical dimensions of packaging data. Understanding this spectrum of issues is the essential first step toward effective data governance and compliance.

For some companies, data might not exist in one place, which makes compliance assessments a challenge.

This data problem can range from data being spread across multiple internal systems (e.g., ERP, PLM, spreadsheets, PDFs) to a much larger issue where it resides externally with suppliers.

This fragmentation makes performing compliance assessments incredibly difficult and time-consuming, often requiring manual effort and increasing the risk of misinterpretation.

Our recommended strategy: Prioritize consolidation into a single source of truth to streamline the assessment process.

Regulations don't just ask what material you use; they often require packaging data to be in a very specific, detailed format. This typically involves a granular breakdown by components (e.g., bottle, cap, label) and additional properties (e.g., opacity, separability, rigidity, barriers) defined for each packaging unit.

Packaging information is also stored in inconsistent formats and terminology: For example, a material may be referred to as "PET," "Polyethylene terephthalate," or "Plastic" in different files or systems.

This lack of regulatory-aligned structure and standardisation makes it difficult to process data automatically, and a lot of manual and time-consuming intervention is required.

Our recommended strategy: Adopt a standardised data structure across your entire portfolio, ensuring you can add supplementary and consistent information as dictated by specific regulatory requirements.

Something that is common across most companies is not having complete information about each and every attribute of their packaging units.

It is important to understand that this is generally not because of human error. Instead, it stems from the inherent nature of packaging regulations.

Regulations were simpler in the past and required less detailed data. Over the years, they have become increasingly complex over time, demanding a substantial amount of additional information.

As these regulations evolve, those responsible for data maintenance cannot realistically track every new requirement, as these differ significantly from country to country and from regulation to regulation.

Therefore, the journey towards complete data is not straight-forward and requires the investment of resources to reach a level of completeness that ensures compliance.

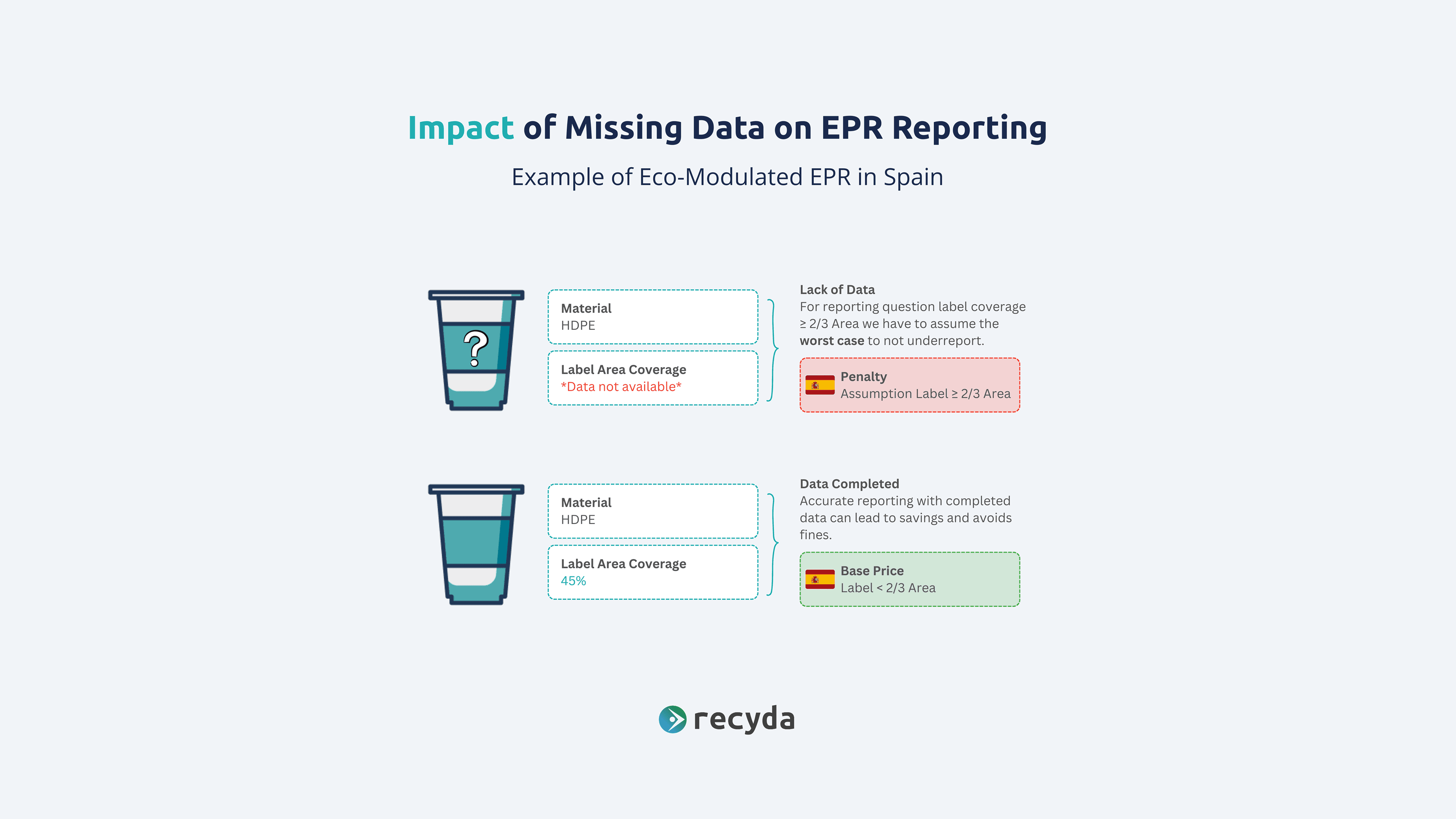

Non-complete data can have implications for compliance:

Non-compliance risks: Even seemingly minor attributes can be crucial for certain regulations. Failing to have this data readily available can significantly increase inaccurate reporting, and hence the risk for fines for non-compliance.

Unclaimed bonuses: in some cases, not having information on certain attributes can result in companies forgoing potential eco-modulation bonuses that companies are entitled to claim.

Our recommended strategy: Work in reverse! Use regulations as a guide to identify required data points, then focus on systematically enriching and completing those specific information gaps.

Lastly, packaging unit information can often be subject to errors or outdated details.

These inaccuracies are likely to occur because of two primary factors:

Data quality is severely impacted by the lack of standardized data protocols and the common reliance on manual data management processes.

The sheer volume of data that must be managed. With thousands of individual packaging units in a portfolio, the statistical likelihood that a few of these might have errors in them is high.

Our recommended strategy: Prioritise data visualisation to help identify outliers and inconsistent data points in your packaging portfolio.

Recyda — Turn Your Data Complexity Into Compliance Readiness

The good news is that these four challenges-Scattered, Unstructured, Incomplete, and Poor data quality-can be overcome with the right data strategy and the right software.

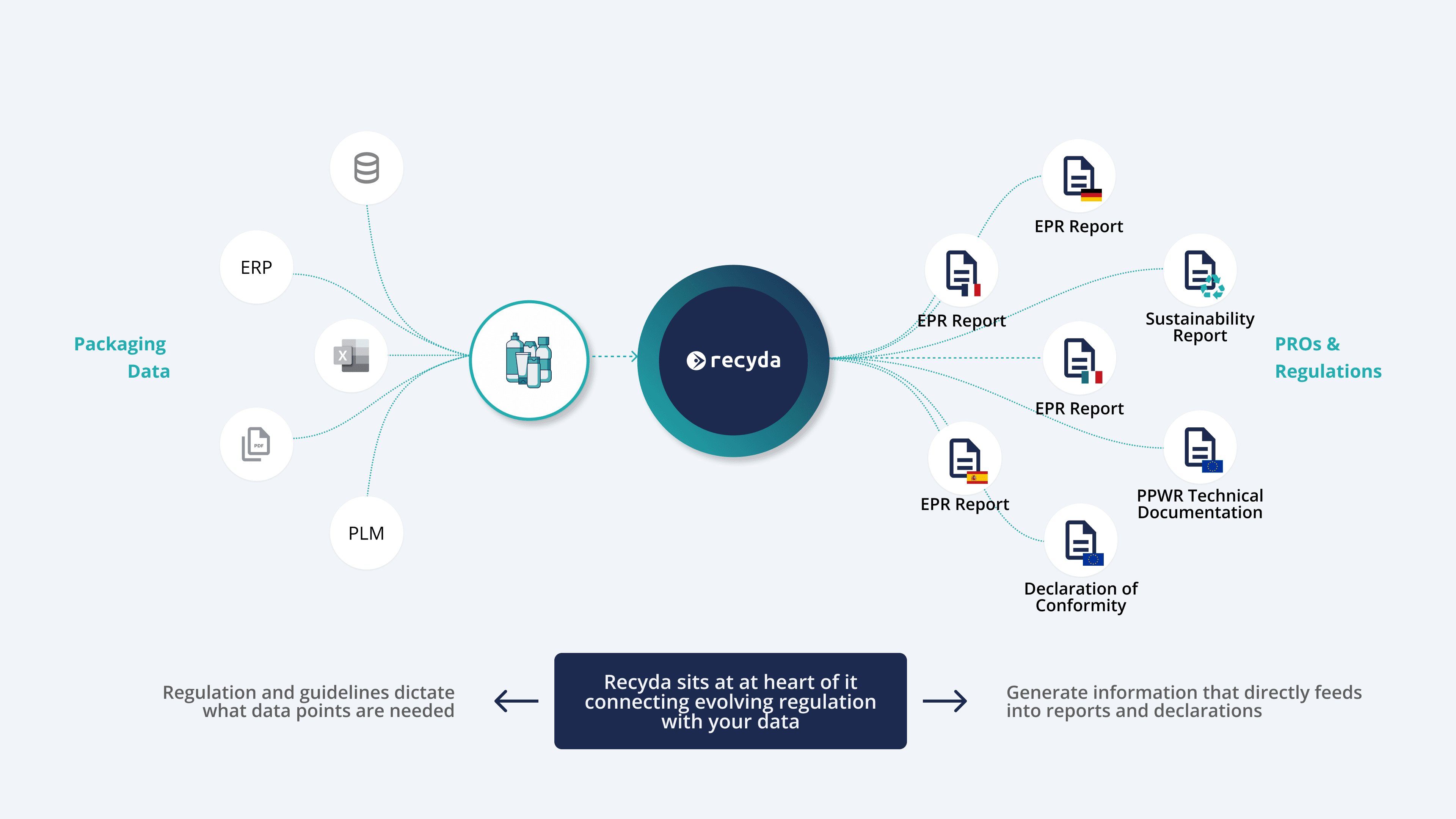

Together with our customers, we have gone through this journey and enhanced their data to be ready for more accurate EPR reporting and readiness for PPWR by leveraging Recyda's platform.

With Recyda, you can systematically consolidate your packaging data, structure it according to regulatory needs, and fill information gaps that are needed to ensure compliance readiness.

Here's an overview of how it works:

Consolidate: bring together scattered data, importing via the API, uploads, file-based mapping, and more.

Structure: map your packaging data onto the structure that optimises it for compliance.

Complete: through a guided workflow, identify gaps and complete your data, ensuring you have exactly what's required for your chosen regulation.

Interested in leveraging our platform to master your packaging data complexity? Learn more about packaging data management in Recyda, or reach out to our team for a personalised demo.